- The world's largest ferromanganese smelting furnace

- Realizing CD (Customer Delight) through detailed customer-oriented service

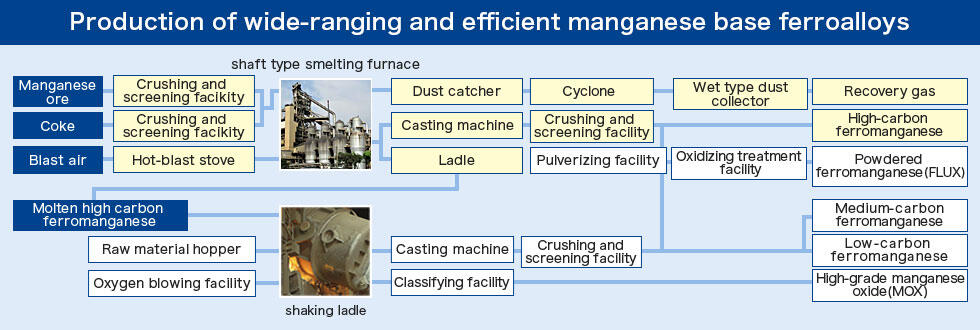

Contributions to the steel industry as Japan's largest supplier of medium- and low-carbon ferromanganese.

High-efficiency stable production technology of No. 2 shaft type smelting furnace

The world's lowest reducing agent rate achieved through high-pressure blast by hot-blast stove and gas distribution control by bell-less type charging equipment

- High Mn yield by high-temperature operation

- Technology using small coke by high-pressure operation

- Smelting technology by which hot metal components can be adjusted from tap to tap

- Life extended by cooling the furnace body and using bricks of high corrosion resistance

- Introduction of computer-controlled integrated electrical instrumentation

| Production capacity | 160,000t/year |

|---|---|

| Installation capacity | 450t/day |

Control room

Tapping

Raw Materialunloading

Raw material stock yard(manganese)

Shaking ladle (SL) realizing quality performance demanded by users

- A variety of grades that can be refined in combination with SF smelting

- Quality stabilized by fully automatic blowing with a sublance and computer

- World's highest level low-nitrogen product manufacturing technology

- Stable and highly efficient production of low-carbon products (C 0.5 ~ 1.0%)

| Production capacity | 100,000t/year |

|---|---|

| Installation capacity/Heat size | 26t/heat |

Teeming

Hot metal charging

Product yard