Iron powder mixing methods are used to purify highly concentrated VOCs pollution quickly.

Unfortunately, the disadvantages of this methods include the requirement of a large plant and the generation of a lots of sludge. Our new foam method; however, uses foam instead of water to resolve the problems with conventional techniques.

New Iron Powder Mixing Method with Space-saving and No Sludge generation

Foam Method Benefits

With conventional method, the ground surface turns into mud because of the large amounts of water supplied to the ground. With the foam method, the amount of water is significantly reduced so that the impact to the ground is minimized.

| Conventional method | Foam method | |

|---|---|---|

| Required water | 135m3 | 9m3 |

| Sludge | 50m3 | 0m3 |

| Plant yard | 20m x 20m | 10m x 5m |

*These values are per internal comparisons. These values can vary depending on the level of pollution and actual conditions.

Calculation conditions: Size of contaminated soil: 10 m x 10 m x 5 m = 500 m3

Iron powder ratio: 5% by weight, Amount of iron powder: 45 t

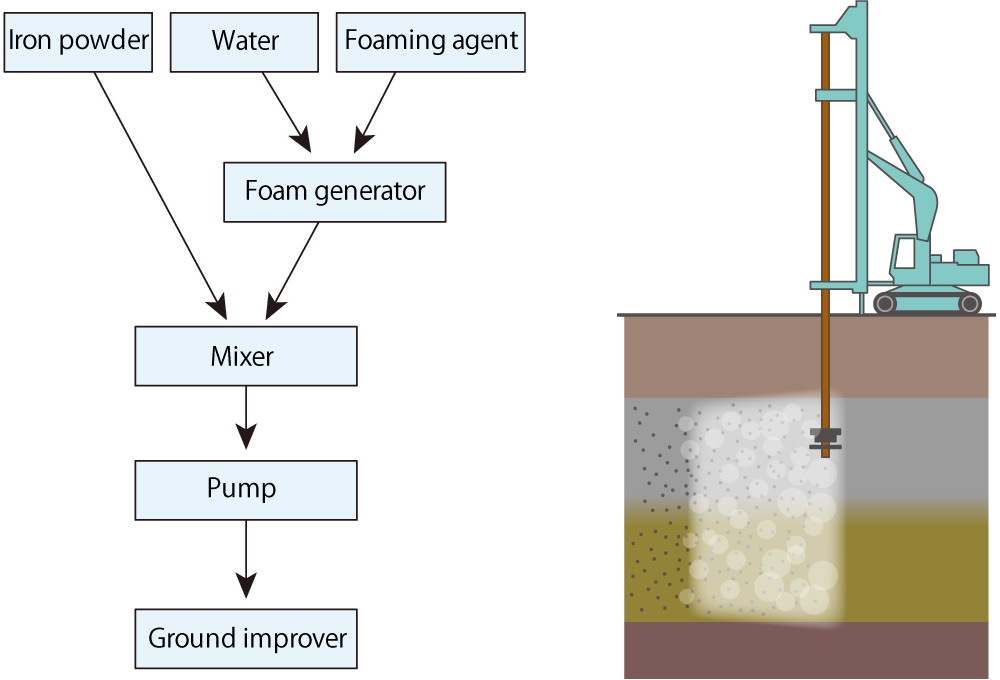

Foam Method Process Flow

States of Operation

Overall view of plant

Mixing stage

Agitator

Contact

Environment Project Dept.

TEL: +81-3-5445-5208 FAX: +81-3-5445-5220

TEL: +81-3-5445-5208 FAX: +81-3-5445-5220