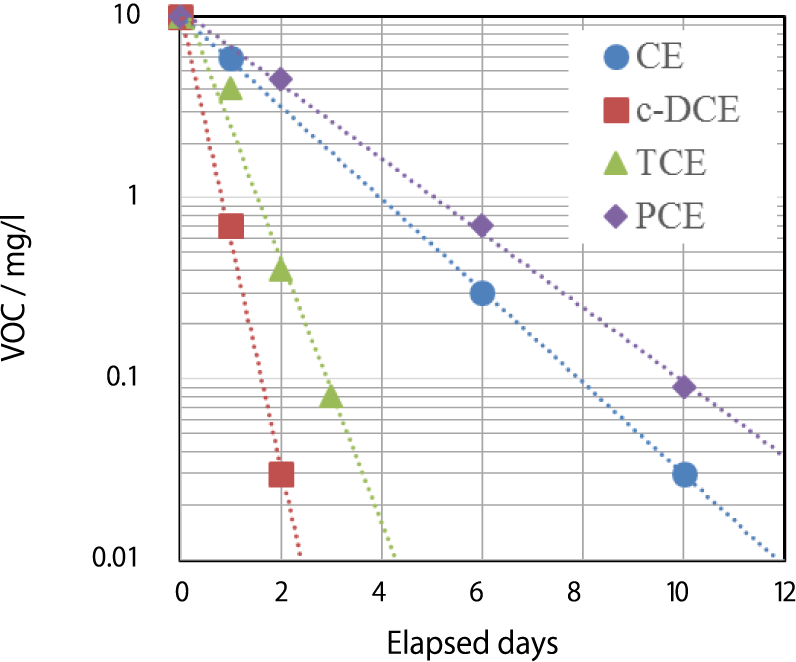

This product is capable of quickly decomposing tetrachloroethylene, trichloroethylene, and other VOCs to environmental standards. This product is also capable of dissolving degradation products such as -1,2-dichloroethylene and chloroethylene.

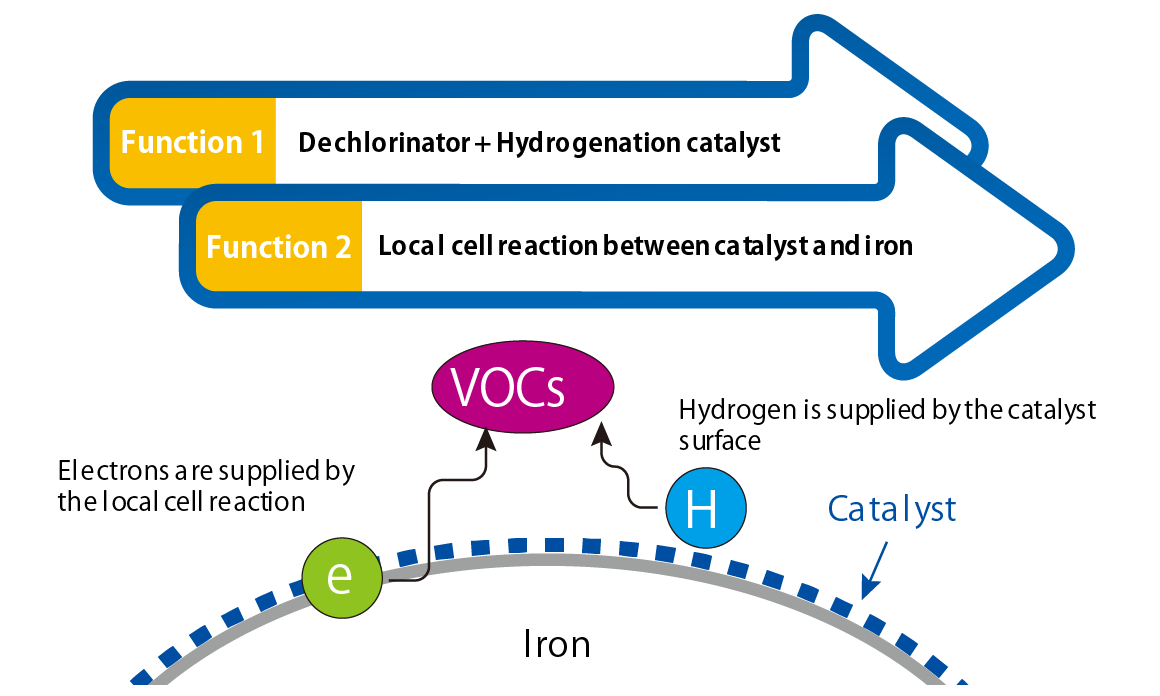

The surface of our MSI-N901T iron powder is coated with a hydrogenation catalyst to increase the speed of VOCs decomposition by the two effects.

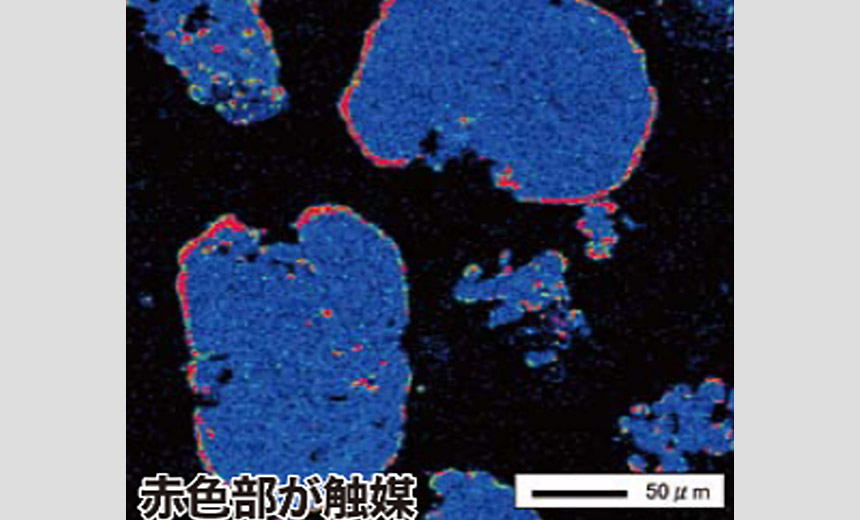

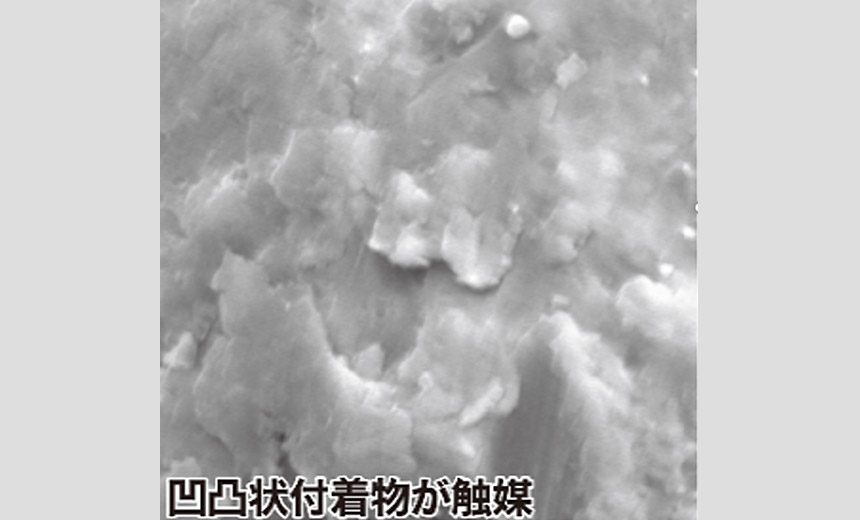

Surface of Pure Iron is Coated with a Catalyst

Cross-sectional EPMA image of iron powder

(The areas in red are the catalyst)

SEM image of iron powder surface

(The rough deposition is the catalyst)

Characteristics of MSI-N901T

Excellent Decomposition Performance for Volatile Organic Compounds (VOCs)

Economic Advantages

Utilizing our expertise in still mill technologies, we have developed an advanced material that requires minimal additives to function. This product is also less expensive than conventional VOC decomposition iron powder.

Excellent Usability

This product can be used in various methods such as mixing into soil, purification walls, and high-pressure, in-ground injection and agitation.

This product is also effective in purification of groundwater as well as soil.

Other Characteristics

- High reactivity due to the use of High-purity iron

- Verified safety - Contains no heavy metals or other regulated substances

- Produces minimal dust and easy to handle

Comparison of VOC decomposition activity

*The provided data is the result of laboratory testing performed according to internal testing methods. Corresponding performance at actual sites is not guaranteed.

Comparison of decomposition performance by VOC

| VOC | Reaction speed constant [h-1] |

Number of days needed to reach reduction of 1/100 |

|---|---|---|

| 1,1,1-trichloroethane | -0.04 | 5 |

| 1,1,2-trichloroethane | -0.04 | 5 |

| 1,1-dichloroethylene | -0.05 | 4 |

| cis- 1,2- dichloroethylene | -0.06 | 3 |

| Trichloroethylene | -0.04 | 5 |

| Tetrachloroethylene | -0.02 | 10 |

| cis-1,3-dichloropropene | -0.09 | 2 |

| trans-1,3-dichloropropene | -0.09 | 2 |

| Carbon tetrachloride | -0.03 | 6 |

| chloroethylene | -0.02 | 10 |

*The provided data is the result of laboratory testing performed according to internal testing methods. Corresponding performance at actual sites is not guaranteed.

Decomposition Performance of Iron Powder by VOCs

MSI-N901T Evaluation via Water Testing

| Substance | Carbon number | Chemical formula | Environmental standard [mg/L] |

Purification performance (O mark indicates that k < -0.01) |

|---|---|---|---|---|

| Dichloromethane | C1 | CH2Cl2 | 0.02 | |

| Carbon tetrachloride | CCl4 | 0.002 | ○ | |

| 1,2- dichloroethane | C2 C-C |

Cl-CH2CH2-Cl | 0.004 | |

| 1,1,1-trichloroethane | CH3-C-Cl3 | 1 | ○ | |

| 1,1,2-trichloroethane | Cl-CH2CH-Cl2 | 0.006 | ○ | |

| Chloroethylene | C2 C=C |

CHl2=CHCl | 0.002 | ○ |

| 1,1 - dichloroethylene | CH2=C-Cl2 | 0.1 | ○ | |

| cis-1,2-dichlorethylene | Cl-CH=CH-Cl | 0.04 | ○ | |

| Trichloroethylene | ClCH=CCl2 | 0.03 | ○ | |

| Tetrachloroethylene | Cl2C=CCl2 | 0.01 | ○ | |

| cis-1,3-dichloropropene | C3 C-C=C |

Cl-CH2- CH=CH-Cl |

0.002 | ○ |

| Trans-1,3-dichloropropene | 0.002 | ○ | ||

| Benzene | C6 | C6 | 0.01 |

*A reaction speed constant k of -0.01 represents the speed constant by which a 1/10 VOC concentration level requires 10 days.

If the 1/10 VOC concentration level requires 5 days, then the k is -0.02. If the 1/10 VOC concentration level requires 2 days, then the k is -0.05.

*The provided data is the result of laboratory testing performed according to internal testing methods. Corresponding performance at actual sites is not guaranteed.

Overview of Iron Powder & Foam Method

Partial Previous Results of Iron Powder Purification

| Pollutants | Tested area (m2) |

Approximate concentration | Depth (GL-m) |

Agents | Method | Soil type |

|---|---|---|---|---|---|---|

| PCE, TCE, cis-1,2-DCE | 500 | Up to 10,000X | Up to 8.0 | Iron powder + Bio-material |

High-pressure injection | Soil with a lot of clay Sandy soil |

| TCE, cis-1,2-DCE | 4,000 | Up to 1,000X | Up to 1.3 | Iron powder + Bio-material |

Mechanical agitation | Soil with a lot of clay |

| PCE, TCE ,cis-1,2-DCE | 100 | Up to 1,000X | Up to 9.0 | Iron powder + Bio-material |

High-pressure injection | Soil with a lot of clay |

| PCE, TCE | 430 | Up to 10,000X | Up to 8 | Iron powder | Mechanical agitation | Gravel |

| cis-1,2-DCE | 1,000 | Up to 1,000X | Up to 2 | Iron powder | Mixed soil | Loam |

| cis-1,2-DCE | 100 | Up to 100X | Up to 3 | Iron powder | Mixed with foam (mechanical agitation) |

Soil with a lot of clay |

| TCE, cis-1,2-DCE | 200 | Up to 1,000X | Up to 25 | Iron powder | High-pressure injection | Loam Soil with a lot of clay |

| PCE, cis-1,2-DCE | 120 | Up to 1,000X | Up to 6 | Iron powder + Bio-material |

Mixed with foam (mechanical agitation) |

Soil with a lot of clay |

*The provided data is the result of laboratory testing performed according to internal testing methods. Corresponding performance at actual sites is not guaranteed.

TEL: +81-3-5445-5208 FAX: +81-3-5445-5220