Stainless steels, Structural steels, Steels for machine structural use, Tool steels

JFE Mineral Co., Ltd. is the only manufacturer of chromium-based alloys in Japan. Our advanced technologies make it possible to refine high quality metals with extremely low impurity contents. In particular, we are the world's leading company in special low-carbon ferrochrome alloys and high-purity metallic chrome.

Main applications

Aircraft parts

Power generating turbine parts

Automotive engine parts

Electronic parts for personal computer

Railway car bodies

System kitchens

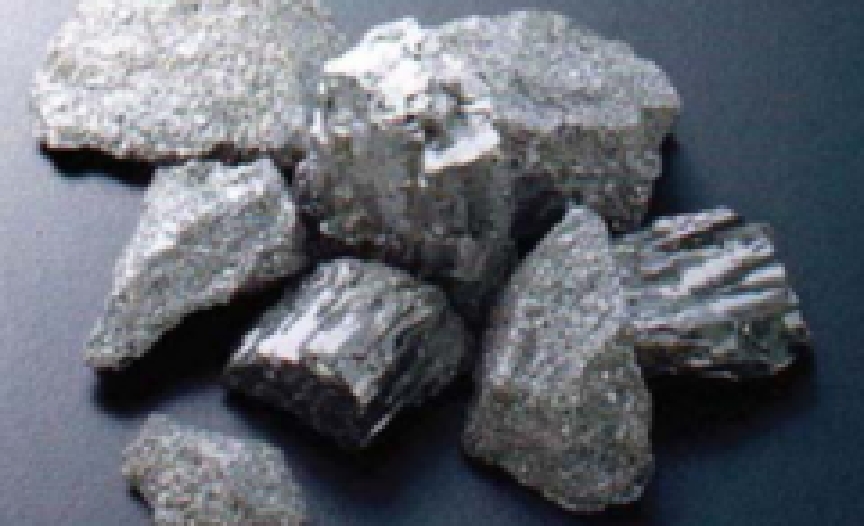

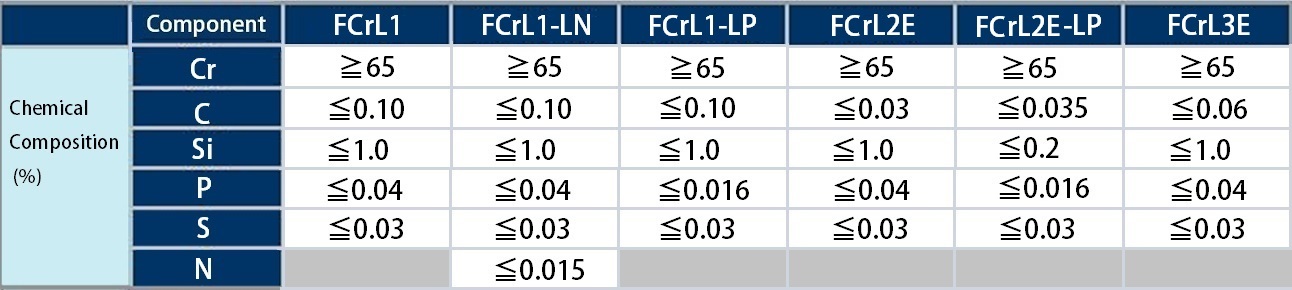

Low-carbon ferrochrome [FCrL]

Low-carbon Ferro Chrome

Carefully selected chromium ore and burnt lime are melted in an electric furnace, tapped, and refined out-of-furnace to produce products that meet the customer's needs.

- Trace elements(C,Si,P,S,N,Co,etc.)are controlled by optimizing the type/amount of raw materials and reducing agents, mixing and reduction reaction conditions, casting conditions, etc.

- Products of various sizes suited to the spectific application can be produced by applying blast machinery and powerful crushing equipment.

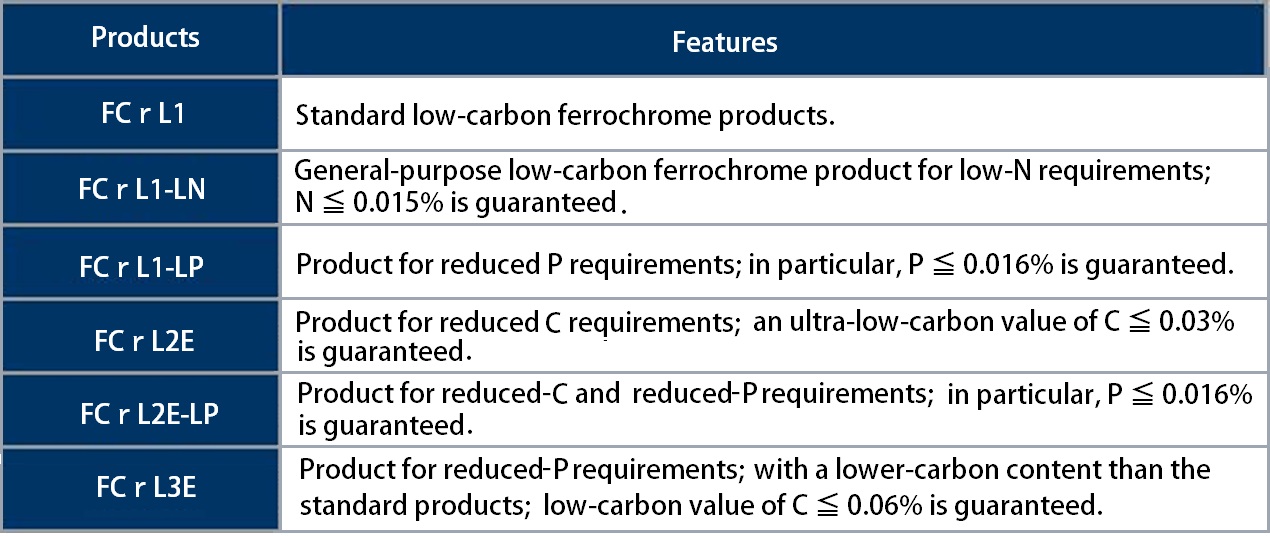

Feature of products

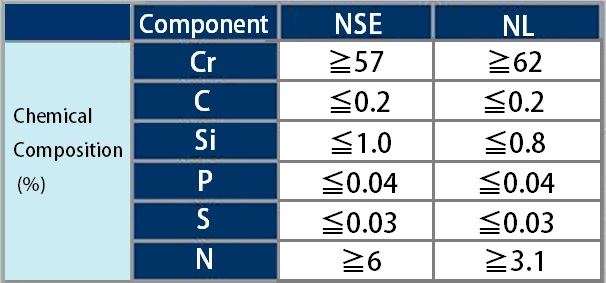

Special ferrochrome

Special Ferrochrome

We supply various types of unique JFE Mineral special alloys, which are produced utilizing vacuum degassing, nitriding, and induction furnace melting technologies.

- JFE JFE Mineral manufactures carbon-free ferrochrome as an ultra-low-carbon chrome source; produced by a large-scale vacuum furnace process.

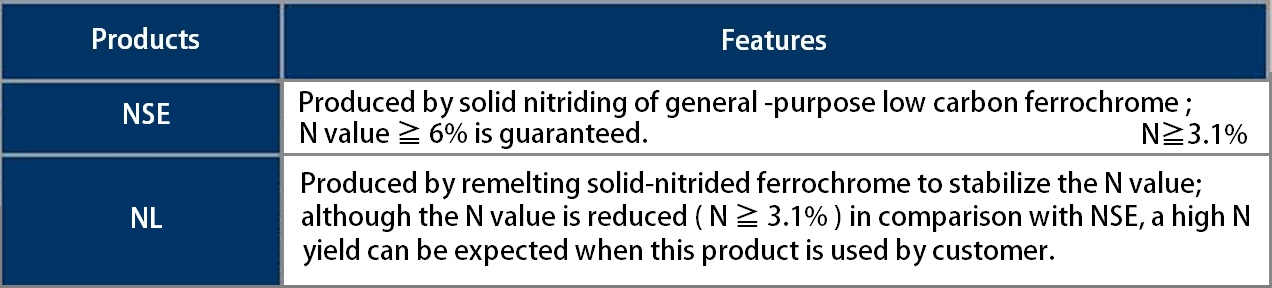

- As a nitriding additive for steel, we manufacture nitrided ferrochrome by a large-scale nitriding furnace process.

We also manufacture melt-nitrided ferrochrome by remelting in an induction furnace.

Feature of products

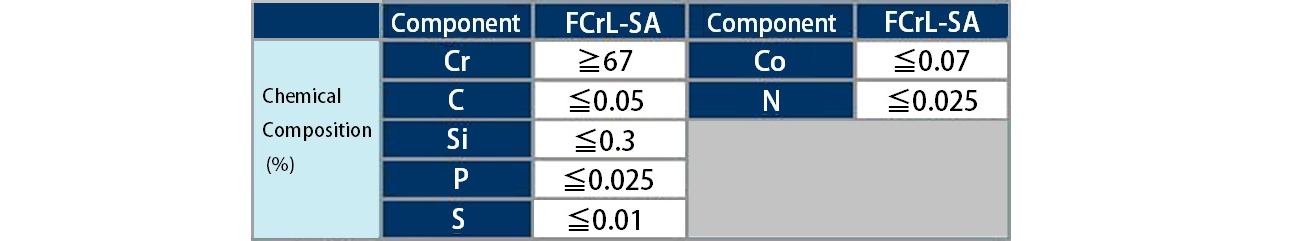

Low-carbon ferrochrome SA [FCrL-SA]

Superalloy Raw Materials

Low-carbon ferrochrome for superalloys (SA) is the culmination of JFE Mineral's outstanding ferrochrome manufacturing technologies.

- Cr component is stabilized at a high level of 68 to 70% by using a combination of raw material treatment technology and electric furnace smelting technology.

- Use of advanced out-of-furnace refining technology makes it possible to control trace elements (C, Si, P, S, Co, N, etc.) to extremely low levels.

- FCrL-SA is a low-cost chrome source that can be used with confidence as a replacement for metallic chrome in superalloys.

![Low-carbon ferrochrome SA [FCrL-SA]](/business/chrome_and_recycle/images/index13.jpg)

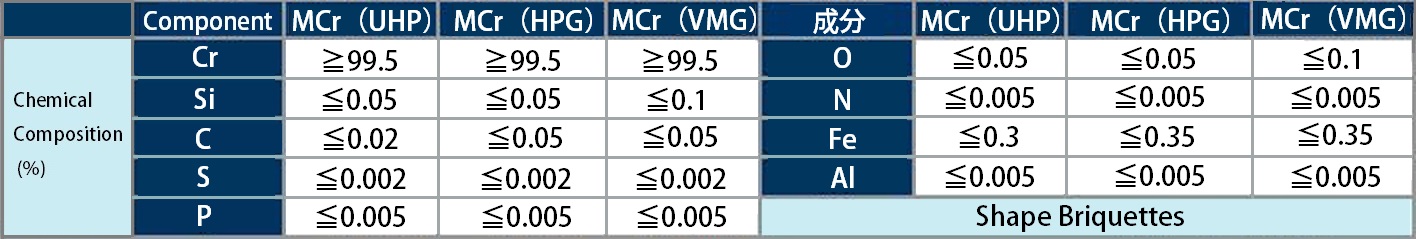

MATERIC CHROME (High-purity metallic chrome)

Superalloy Raw Materials

Using a unique manufacturing process, JFE Mineral supplies high purity metallic chrome with purity exceeding 99.5% as a chrome source for superalloys, mainly for use in aircraft.

- High purity products with Si, Al, and S stably reduced to previously-impossible low levels by utilizing electric furnace two-stage refining technology.

- Gaseous components (N, C, O) are stabilized at extremely low levels by a degassing process using a large-scale vacuum furnace.