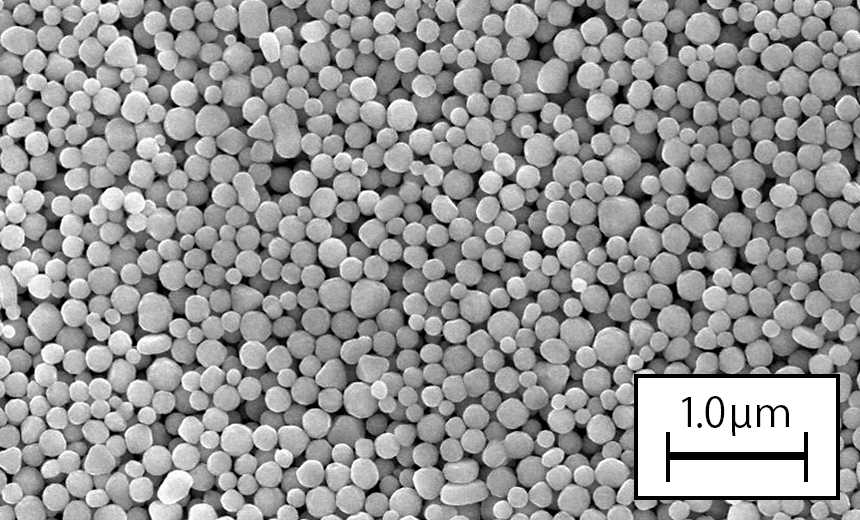

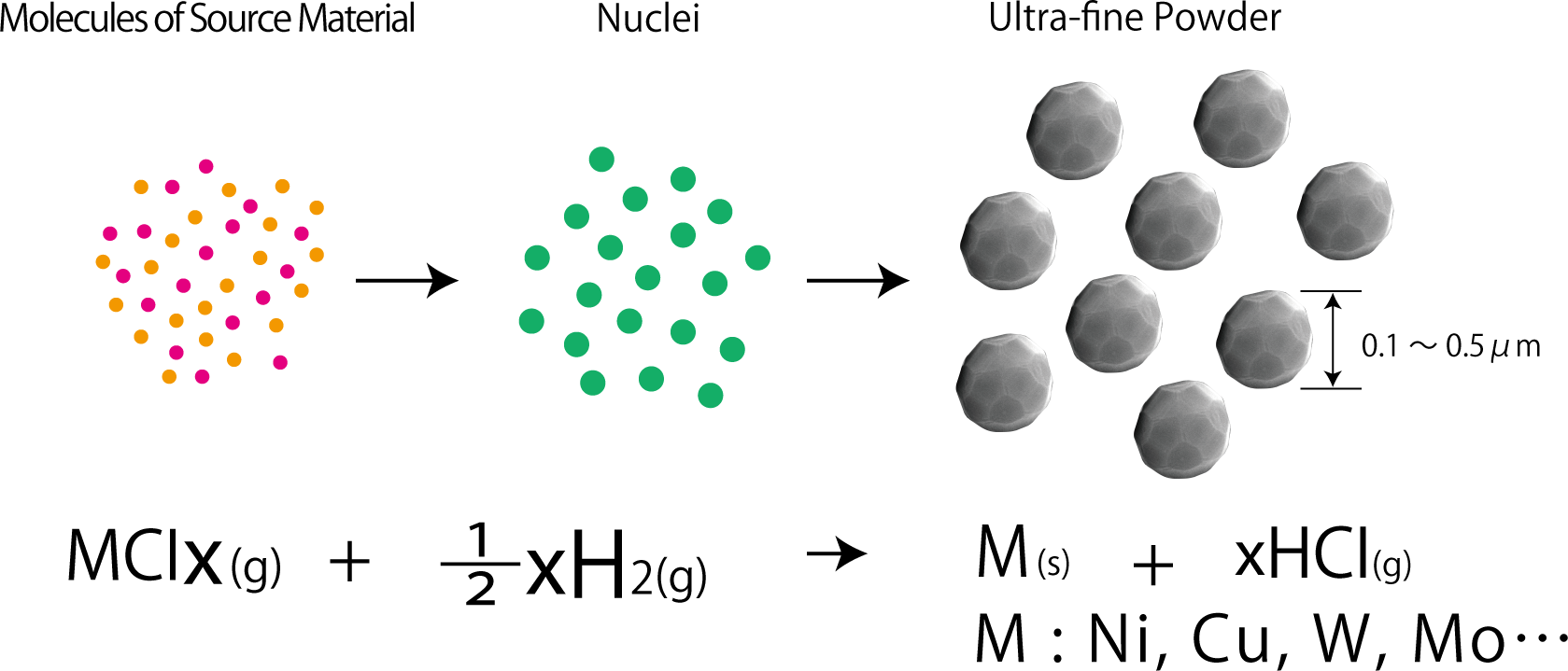

Along with the rapid development of information networks, compact and lightweight electronics components are now playing an increasingly pivotal role in the IT revolution. The development of such advanced, high-performance, and compact products owes much of its success to the use of new functional materials in making electrodes and wiring material. We developed ultra-fine powder nickel in 1995 and have seen tremendous growth of this product for use in internal electrodes of multilayer ceramic capacitors.

Ceramic capacitors are important electronic components that function together with diodes to convert alternating current (AC) into direct current (DC) and to significantly reduce high-frequency signal noise. A typical high-performance smartphone, for example, contains 700 to 800 of these ceramic capacitors.