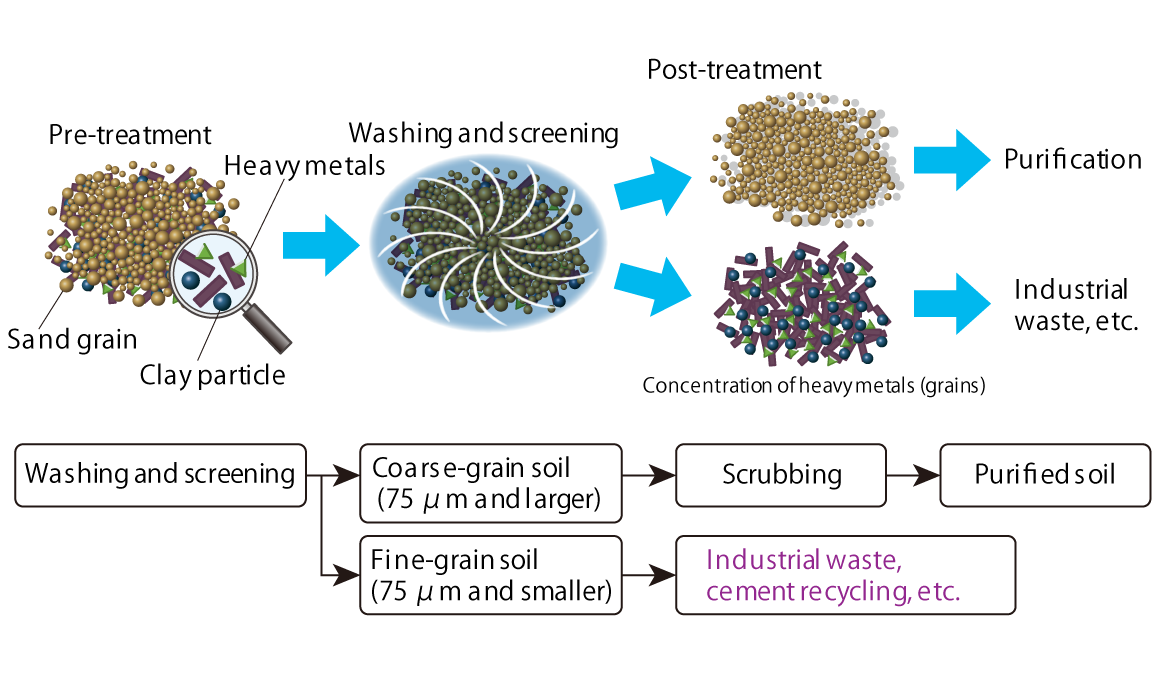

With traditional soil washing techniques, processing costs were required to deal with the fine-grain industrial waste that would always be produced.

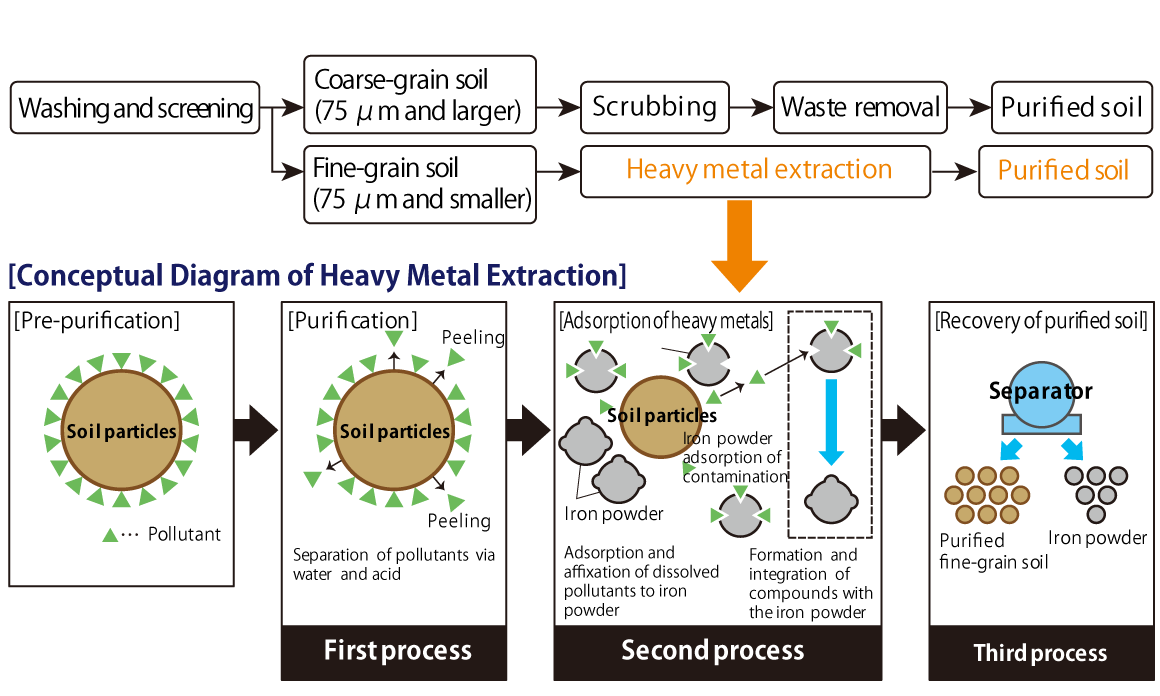

With MSI-X, we can even purify fine soil particles traditionally handled as industrial waste.

Comparison with Conventional Techniques

Soil Washing Process Flow Using Conventional Techniques

Our Proposed Solution for Fine soil particles

- Using MSI-X enables purification of any type of soil and even fine soil particles traditionally handled as industrial waste.

- Reusing recovered iron powder also has the potential to reduce costs.

MSI-X Characteristics

Iron Powder Made from Pure Iron

- Does not easily scatter due to a high specific gravity and a particle size that is not too fine. (high workability)

- The Fe dissolution over long periods of time ensures high adsorption properties.

- Minimal impact on the surrounding environment due to a neutral pH.

- Easy separation and recovery after adsorption due to strong ferromagnetism and high specific gravity.

Chemical Surface Treatment

- An increased specific surface area improves reactivity and adsorption performance.

- Surface is chemically treated for high initial reactivity.

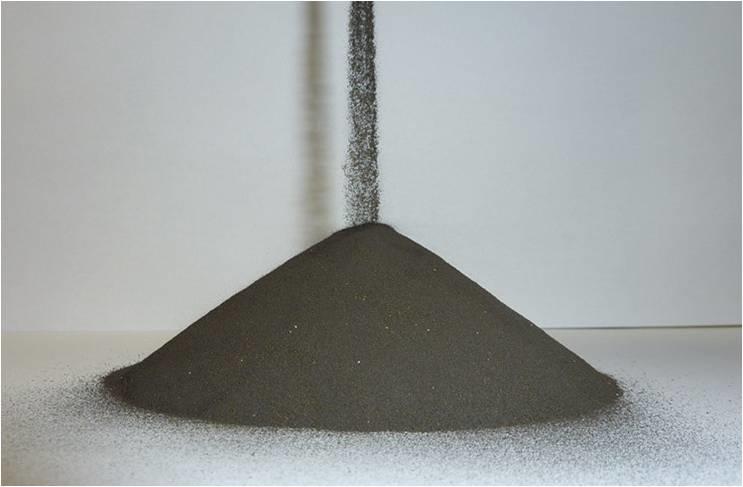

Sample of MSI-X

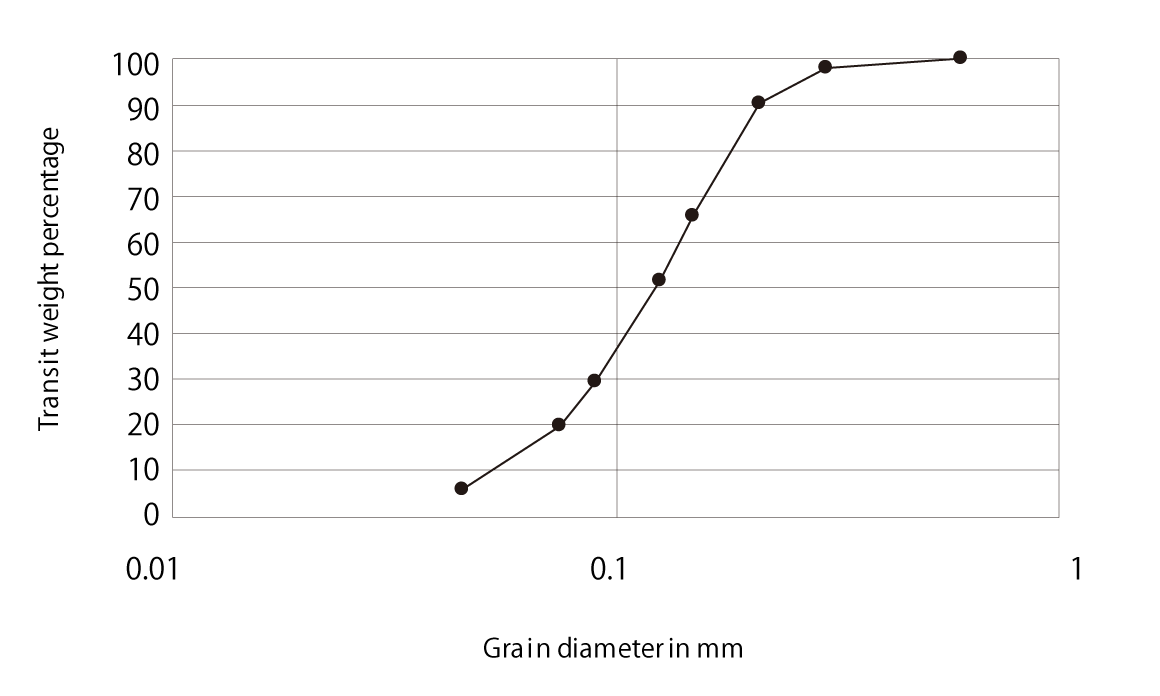

MSI-X Physical Properties

| Main component | Fe (90% minimum) |

|---|---|

| Bulk density (g/cm3) | Ave.3.0 |

| pH | 6-8 |

| Particle diameter (μm) | Ave.130 |

Particle Size Distribution of MSI-X Iron Powder

SEM Image of Iron Powder Surface

MSI-X Performance

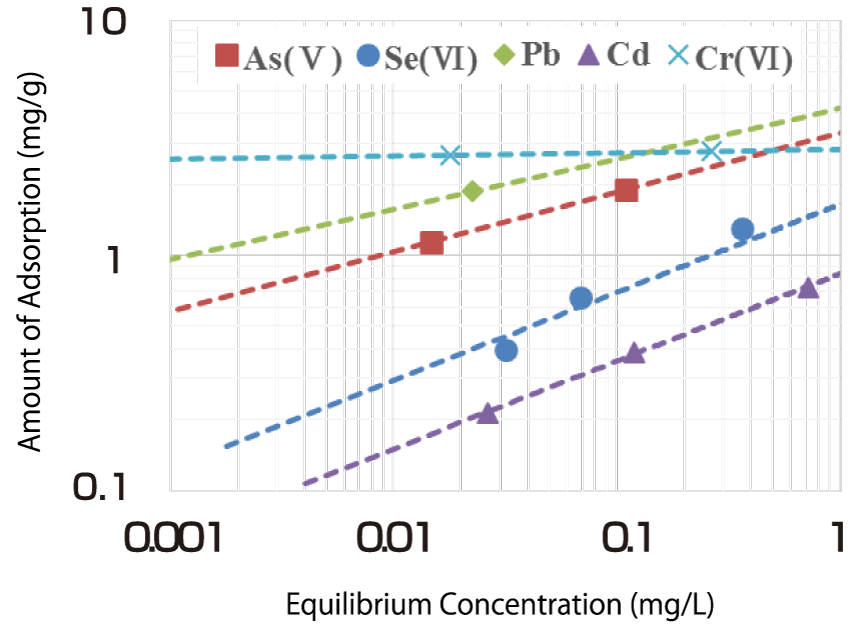

MSI-X Metal Adsorption Isotherms

*The provided data is the result of laboratory testing performed according to internal testing methods. Corresponding performance at actual sites is not guaranteed.

Adsorption at Equilibrium Concentration per Environmental Standards

| Element | Environmental standard (mg/L) | Adsorption (mg/g) |

|---|---|---|

| As(V) | 0.01 | 1.0 |

| Se(VI) | 0.01 | 0.3 |

| Pb | 0.01 | 1.6 |

| Cd | 0.01 | 0.2 |

| Cr(VI) | 0.05 | 2.7 |

*The provided data is the result of laboratory testing performed according to internal testing methods. Corresponding performance at actual sites is not guaranteed.

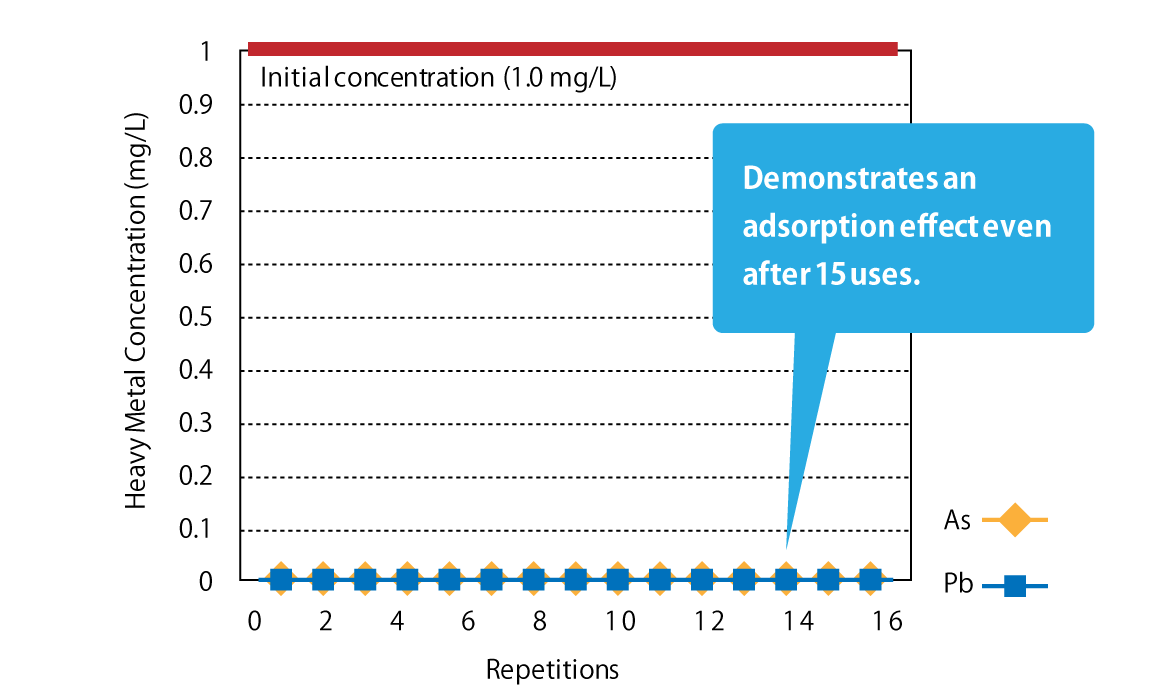

Repeated Adsorption Testing of Arsenic and Lead

| Initial Concentration | (1) As solution: 1.0 mg/L (2) Pb solution: 1.0 mg/L |

|---|---|

| Amount of additive | 3wt% |

| Agitation time | 10 minutes |

| Repetitions | Recovered MSI-X was added to the As and Pb solutions 15 times using the same procedure. |

*The provided data is the result of laboratory testing performed according to internal testing methods. Corresponding performance at actual sites is not guaranteed.

Comparison with Conventional Techniques

MSI-X is used in various purification processes.

This product is used to treat muddy water that contains heavy metals such as arsenic and soil contaminated with heavy metals.

Actual Example Projects

| Project summary | Applications | Comments |

|---|---|---|

| Company A Heavy Metal Remediation Project | Groundwater remediation | - Mechanical agitation to remove arsenic |

| Prefecture A Heavy Metal Remediation Project | Heavy metal remediation | Magnetic separation using washing and fine-grain screening |

| Prefecture B Shield Project | Shield construction remediation | - Magnetic separation to remove arsenic |

TEL: +81-3-5445-5208 FAX: +81-3-5445-5220