Even natural sand previously thought to be in virtually inexhaustible supply is becoming harder and harder to find in good quality. This has created a risk of decreased strength and durability of concrete. However, using sand made from blast furnace slag has serious potential to make concrete even better.

Blast furnace slag fine aggregate received the JIS A 5012 certification in 1981. The Architectural Institute of Japan and Japan Society of Civil Engineers have also published guidelines on the use of this material. Today, this JIS certification has been revised to JIS A 5011-1 (concrete slag aggregate) and has also been added to JIS A 5308 (ready-mixed concrete).

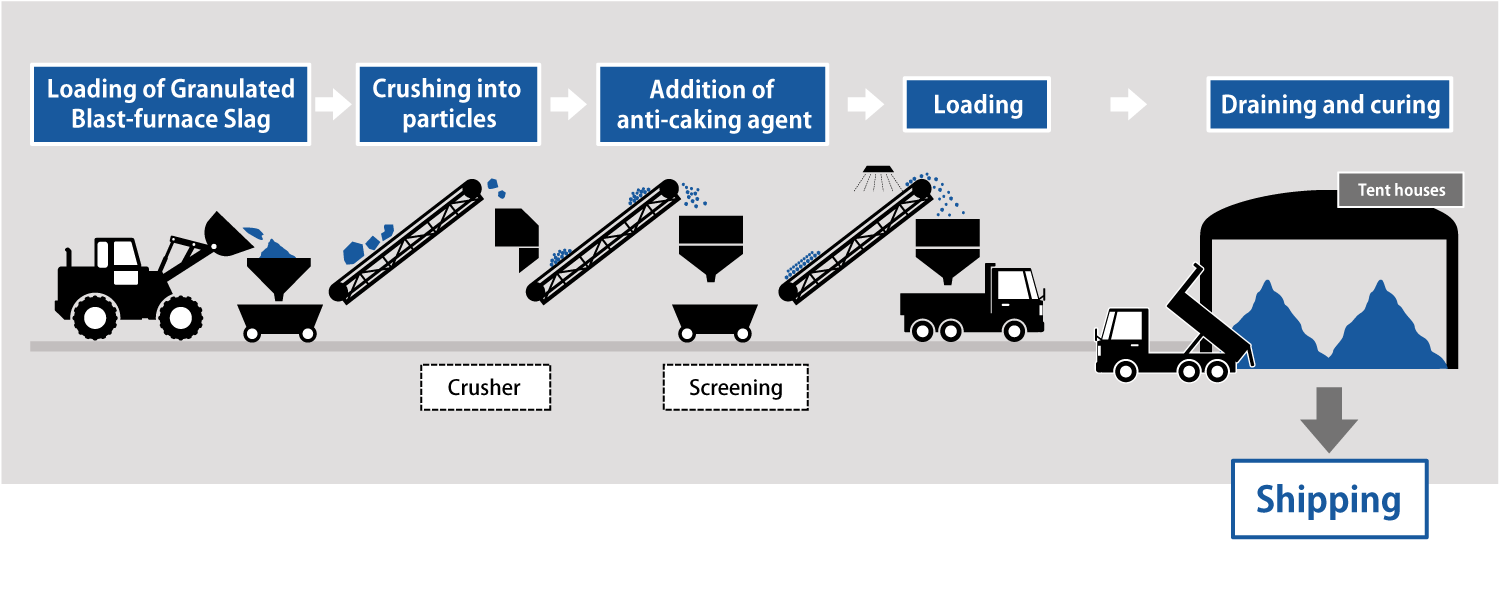

Our blast furnace slag fine aggregate is used as an environmentally friendly substitute for natural sand.